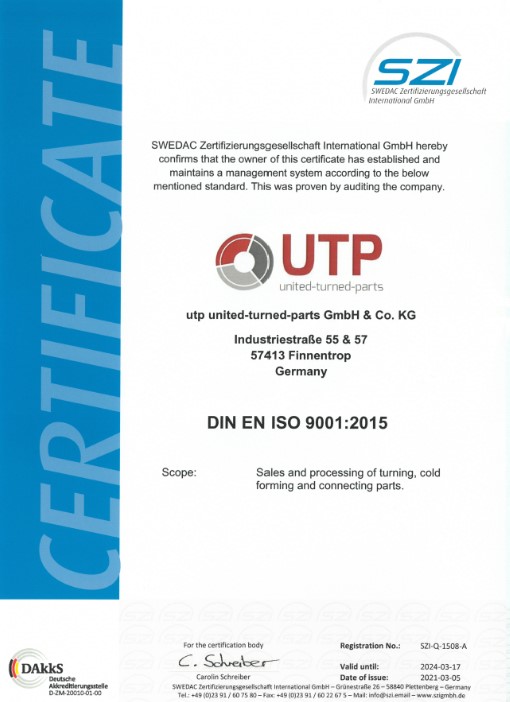

WE ARE CERTIFIED

Quality is and remains an important key factor for success in a company. DIN EN ISO 9001 is the most important and most important standard in quality management.

It is a globally recognized standard that defines various minimum requirements for effective quality management.

A key purpose of the ISO 9001 standard is a kind of statement and statement about the quality of the products in a company. More and more customers pay attention to the ISO 9001 certification when choosing their suppliers.

We work consistently according to DIN EN ISO 9001: 2015 and IATF 16949

In addition, we have obtained the certificate

DIN ISO 14001: 2015

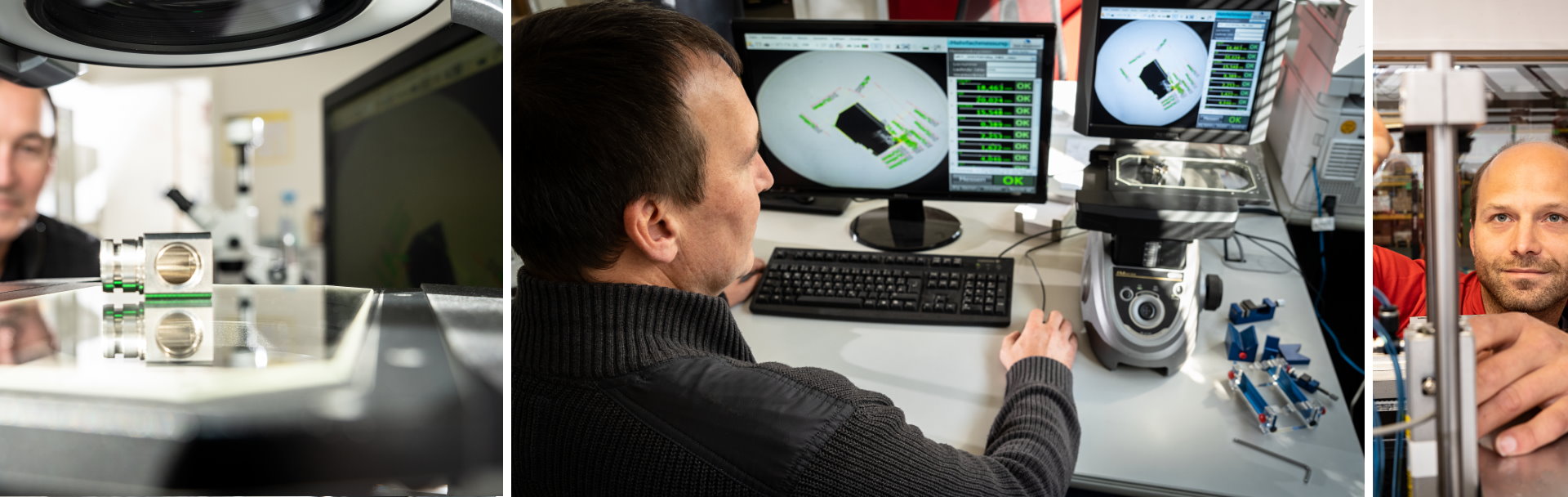

Time is money. We guarantee zero downtime or delays as a result of defective parts when delivering material to our customers’ production plants, which could disrupt production or lead to subsequent customer claims. We offer our customers a zero-defects strategy. All parts manufactured by UTP are inspected from top to bottom using in-house optoelectronic sorting machines, which have been designed and constructed for UTP systems for this purpose. Even the smallest of deviations from the defined specifications are detected and the part rejected. In addition, UTP specialists carry out inspections to ensure each delivery to your production is expertly packaged and carefully prepared. The zero-defects strategy reflects our pledge of perfect collaboration.

Innovative Qualitymanagement

The utp products are 100% checked on our own specially built optoelectronic sorting machines.

This enables utp to have a zero-error strategy..